In the next 5 years I think we’re going to see a big shift in how analytics and Quality Control are done for mRNA manufacture.

Personalised mRNA therapies are coming and will challenge established analytical technologies: Should we look to the diagnostics sector for improved Quality Control?

By Piyush Chaturbedy & Dr. Zoltán Kis

Together with Dr Zoltán Kis from the University of Sheffield, we’ve explored what Quality Control (QC) will need to look like to deliver personalised cancer mRNA vaccines in the clinic. To achieve rapid manufacture of safe and cost-effective therapies, new techniques will be required – in this article we’ve zeroed in on three areas of innovation.

The success of mRNA vaccines in ending the Covid-19 pandemic has propelled mRNA technology years ahead. Barely three years since the approval of the first such vaccine, more than 800 mRNA drugs are in development.

In addition to mRNA vaccines against infectious disease, personalised mRNA-based cancer vaccines are progressing through clinical trials. These therapies may be tailored to an individual’s tumour by encoding patient-specific neoantigens in mRNA to train the immune system on the cancer. The UK Government wants to make such therapies available to cancer patients by 2030.[1]

Previously, we’ve looked at the scalability of manufacturing personalised cancer vaccines. Now we’ve explored the QC challenge in bringing these therapies to patients together with Dr Zoltán Kis from the Department for Chemical and Biological Engineering at the University of Sheffield.

For prophylactic vaccines it’s about the number of doses, but for personalised cancer therapeutics the challenge will be about speed, he explains. “Personalised cancer vaccines will ultimately need to be delivered to patients within days of neoantigen identification. This will require a shift in perspective for developers of manufacturing equipment,”

In particular, it means decentralised manufacturing. To cut shipping times, to simplify the logistics around manufacturing individualised drugs, and perhaps also to eliminate the need for any post-shipping quality control, personalised cancer vaccines will need to be manufactured on the hospital premises or in city-wide or regional manufacturing facilities.

While this is possible in principle for mRNA vaccine design and cell-free manufacturing, meeting these turn-around times is a challenge with existing approaches to quality control (QC) – without which therapeutic products cannot be released to the patient.

If this seems daunting, it’s worth remembering that in recent years, we’ve seen a similar evolution to more “at-line” analytics in the diagnostics industry – meaning close to real-time measurement with small-footprint instruments in the physician’s office, rather than a central diagnostics laboratory.

In this Insight we draw on TTP’s experience in the diagnostics industry to look for parallels that could help us tackle the mRNA manufacturing Quality Control challenge.

What mRNA manufacturing looks like today

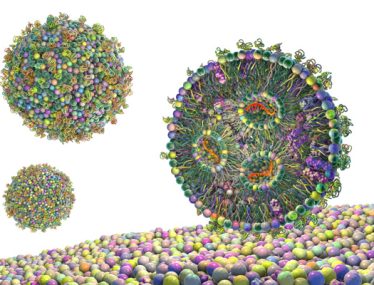

Because mRNA vaccine manufacture is a multi-step process, where each step has a different product (DNA, RNA, nanoparticles, etc), diverse analytical tools are required to assess the quality and purity of these products. Currently, 20-25 critical quality attributes (CQA) are typically checked before a batch can be released.

In addition, at present, QC is largely off-line and relies on central-lab analytic instrumentation (such as RT-qPCR, sequencing, capillary and gel electrophoresis, RP-HPLC, immunoblotting, DLS, etc). Sample preparation for different analyses is largely carried by expert technicians and often requires large samples and protocols with lengthy turn-around times. With future decentralised manufacturing suites in mind, the instrumentation is also often onerous and expensive to maintain and occupies many times the bench space of the manufacturing equipment.

Finally, to the extent that current QC relies on monitoring the mRNA manufacturing process, the existing process analytical parameters and methods of product quantification provide little insight into product identity and purity, which are critical for the safety of advanced therapy products.

So although “quality by design” approaches to mRNA manufacturing processes may ease the eventual QC requirements, equipment manufacturers need to start specifying the analytical technologies that will be needed by the sector.

How know-how from diagnostics can help

In this context, it’s worth remembering that the diagnostics industry has been remarkably successful in increasing the efficiency with which personalised results can be delivered.

Many of the analytic techniques used in diagnostics have been translated into technologies that enable simple deskilled assays or integration into miniaturised formats or automated instruments with fast results read-out. Sample volumes have also shrunk on the back of newer analytical methods in combination with assay miniaturisation and implementation in automated and increasingly microfluidic systems.

More recently, the distribution of diagnostics to the point of care has cut out the time of shipping samples to central laboratories, and the need for diagnostic results within the duration of a doctor’s appointment has been met through the development of technologies for faster results read-out – for example with TTP’s Lex PCR technology.

Testing in near-patient and clinical settings has also benefitted from the miniaturisation of equipment to run assays outside of traditional laboratories. Standard laboratory techniques have been replaced with small cartridges pre-filled with stabilised reagents. It’s now possible for an operator to run a diagnostic assay by simply adding a sample to a cartridge, followed by automated results generation.

The upshot is that there is a wealth of experience in diagnostics that can inform the development of purpose-built, miniaturised instruments to support distributed manufacturing of personalised mRNA cancer vaccines and associated analytics.

Three areas for innovation to decentralise mRNA manufacturing QC

Diagnostics can provide the know-how, but what are the key areas to focus on to enable the decentralised production of personalised cancer vaccines?

Monitoring the “health” of the manufacturing process

One area we should focus on is better monitoring of the mRNA manufacturing process that will speed up batch release by reducing the need for downstream workup and QC. This will require more informative process parameters that can ideally be measured “in-line” and provide insight into product identity and purity.

In addition to physical and conventional measurements that are currently underutilised or unnecessarily cumbersome, new technologies such as “third-generation” sequencing could be part of the answer. For example, Oxford Nanopore Technologies (ONT) and the University of Queensland are developing direct long-read mRNA sequencing to assess mRNA integrity and purity in real-time.[2]

“The key challenge here is that such a technique needs to be sensitive enough to pick up error rates in the range of 1 in 5000 for IVT reactions,” says Kis. TTP has specified a monitoring-by-sequencing solutions in recent work with the Earlham Institute and Natural History Museum.

Simultaneous monitoring of multiple such process parameters, and analytics focused on correlations between them, could give us better insight into “health” of the manufacturing process – just as we are currently seeing in diagnostics – and adherence to the target product profile (TPP).

Faster, smaller, and de-skilled technologies for “at-line” and “off-line” Quality Control

Process analytics alone may not be enough to release personalised cancer vaccines to patients. Some parameters and CQAs may need to be measured either at-line or off-line, without delaying the release of the therapeutic product.

Again, diagnostics can give us confidence. Diagnostic PCR instruments have been miniaturised and sample-to-answer times have been cut by an order of magnitude for point-of-care applications.

There is no reason why we shouldn’t try to achieve the same for technologies critical to the speedy release of individual cancer drugs – for example by specifying them precisely for analytic task at hand, rather than using general purpose analytic instruments.

Automated sample preppers like in point-of-care diagnostics

Last but not least, as part of the decentralised production of individual drugs, QC samples will need to be moved from manufacturing lines to analytic instrumentation.

This calls for automated equipment to draw drug product samples, prepare them for analysis, and transfer them to analytical instruments to reduce technician hands-on time and reduce the manufacturing footprint. Automated and miniaturised sample preparation devices have been a key enabler for the rapid point-of-care diagnostics.

Outlook

Diagnostics has solved many of the challenges that can be anticipated as personalised cancer vaccines move into the clinic. The question now is, can we develop the necessary QC technology in time? Kis is optimistic: